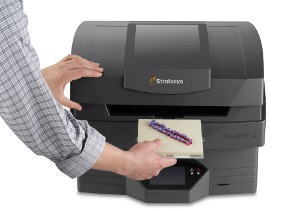

Stratasys Ltd., a global leader of 3D printing and additive manufacturing solutions today introduced the highest precision wax 3D printers available to the dental industry.

The Stratasys CrownWorx and FrameWorx 3D Printers allow dental laboratories to produce wax-ups for crowns, bridges and denture frameworks. The machines will be unveiled May 17 at the LMT Lab Day West Show in booth number B8.

Stratasys CrownWorx and FrameWorx 3D Printers use wax deposition modeling technology, a jetting technology that is designed to enable consistent quality and a reliable process. The machines produce superior-fitting wax-ups for crown, bridge, coping and denture frameworks via an automated method that can fit easily into a lab’s established workflow, enhancing production capacity.

Stratasys CrownWorx and FrameWorx 3D Printers use wax-like materials that produce smooth surface finishes and minimize post-processing. The materials burn-out with no residue, material shrinkage, cracking or expansion to allow precision casting and reduce costs previously incurred when finishing gold and other precious metals.

Stratasys CrownWorx

Based on resolution, the CrownWorx 3D Printer is best-in-class for creating crown, bridge, and coping wax-ups. CrownWorx uses WDM Technology to jet micro-drops of TrueCast material that builds dental wax-ups, layer-by-layer.

Stratasys FrameWorx

The FrameWorx 3D Printer uses WDM Technology to jet micro-drops of TrueCast material onto the build tray to create a denture wax-up layer-by-layer. TrueSupport material is quickly sprayed around the casting material to form a support structure. This enhancement increases production speed for partial denture wax-ups because they require more support material than crowns and bridges. After printing, TrueSupport is dissolved, leaving behind smooth and detailed wax-ups.

“These wax 3D printers and new materials are an ideal fit for small labs interested in upgrading dental casting technology,” says Stratasys Director of Global Dental, Avi Cohen. “We believe dental labs adopting these 3D printers will benefit from the automated and digitized workflows, enabling them to cut costs while producing more restorations. These systems complement our broad system portfolio, which includes large dental 3D printers.”

TrueCast and TrueSupport

TrueCast is a firm but flexible material that mimics real wax and allows labs to 3D print any dental wax-up with extreme accuracy. It is 100 percent castable for any alloy. TrueSupport is a true wax-blend material that is automatically generated to protect a wax-up during printing. It has a low melting point that produces delicate restorations and is easily removed from each wax-up, after production.

More information about CrownWorx, FrameWorx, TrueCast and TrueSupport is available atwww.StratasysDental.com.

Source: http://www.stratasys.com/