The next time I go to Indianapolis it's going to be by plane and not by car. It was a last minute decision on whether to make the trip or not. Thus when I looked at the flights and saw that the cost was almost a thousand bucks, I decided the make the drive. On the way out I did two six hour drives and stayed over night in western PA. But, the trip back I had to make in one day. It was fourteen hours from start to finished and I was mentally drained by the time I arrived home in Highlands.

Muratec America

A few weeks ago I was notified by my friends at Muratec America (Division of Konica Minolta) about the InfoFlex Event in Indianapolis. The InfoFlex event is for those businesses and professionals that use the process of flexography to print labels.

Here's the definition.

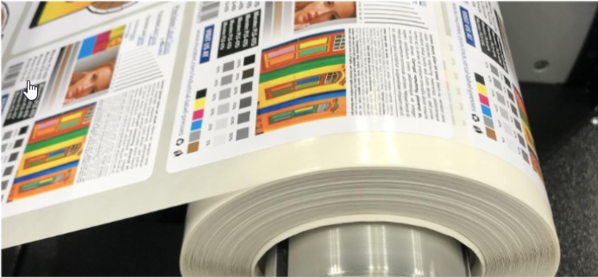

Flexography (often abbreviated to flexo) is a form of printing process which utilizes a flexible relief plate. It is essentially a modern version of letterpress which can be used for printing on almost any type of substrate, including plastic, metallic films, cellophane, and paper.

Flexography

There's a few reason why I wanted to go. For starters a recent blog from GAP Intelligence stated that the digitization rate of four percent. That means that only 4% of the presses in use are digital. That market is ripe for the penetration of digital label presses. In addition, there are not many players offering digital label presses.

Secondly, I needed to learn more about Flexography and how those presses work. My last reason was to learn more about the label presses that are being offered by Muratec America. It's a different world from copiers, however it's a channel that is still thriving and when it comes down to it, it's all about putting ink or toner on substrates.

I walked the show floor twice before I gathered up the gumption (I had no clue as to what 90% of the vendors were selling) and thought of the questions that I wanted to ask. To everyone, I introduced my self as a beginner with Flexography. To my surprise everyone was willing to answer my questions and help me better understand flexography. Everyone that I spoke to was aware that digital presses (ink or laser) is the wave of the future.

Takeaways

1) My biggest take away is that Flexo presses are very similar to off-set presses. There are still plates, make readies (labels), waste, press cleaning, drum cleaning and set up times. Can take up to 25 minutes to

2) Flexo Presses can start at about $800K and go in to the millions of dollars!

3) Short run labels of 500-5,000 are frowned upon especially if they have a wide web flexo press.

4) Flexo Presses can create full color labels capable of cold foil, spot varnish and variable printing. Cost is measured in MSI (cost per one thousand square inches).

5) Flexo printing at least with some of the older devices still needs a craftsman to dial in the press and make it hum. Same as off-set.

6) There are no generic digital inks for Memjet or PageWide print heads. At least that's what I was told. I did have a conversation with a rep from TOYO inks and he stated that they do have a digital ink division (suggested that I speak to someone in their digital ink division), however they may have a relationship with HP.

Direct Correlation

For me the beginner, I see the direct correlation between off-set and Flexo for the placement of digital label presses. For those that want to get into this lucrative field we can take the same path that we used to replaced off-set presses many years ago. We're not go to be able to replace those Flexo presses at the start, however what we can offer is an alternative digital technology that can enhance a company that is using Flexo Presses. We need to address and attack the short run orders that that are turned away or are making a much smaller margin. Focusing on those short run orders to find placements for digital label presses.

Consumables & Maintenance

Ink, ink and more ink. Since there seems to be no generic inks available, selling label presses that uses the Memjet or PageWide print heads will make your dealership the "go to" source for the ink. If you're thinking about click charges there is none. Maintenance Agreements should be billed as "device billing", which means that the dealership can charge a month or annual cost with unlimited usage.

Comment

After a recent post on Linkedin about the event. Ray Stasieczko offered the comments below.

"Not without a solid business plan to understand the market potential and true cost to deliver. A dealer selling 5 or 10 won’t provide the ROI. These are no different than Production Print equipment too many chase revenue instead of profit".

I'm in agreement with the need for a solid business plan. But I'm not in agreement with the statement of a dealer selling 5-10 presses won't provide enough ROI. With an average selling cost of $45K per press, the sale of 10 presses will create almost a cool half a million of revenue. All of the ink consumables will be captured by the dealer, and depending on price a dealer may be able to capture much of the substrates that will be used.

Ray also stated that these label presses are no different that Product Print. I'm also in agreement with that. If your dealership is successful with selling Production Print, then the Label Presses should be a no brainer to move forward with. Think of it this way, if you can't get in the door with a Production Print, you may be able to create excitement and get in the door with Label Presses.

"Too many chase revenue instead of profit". I hear you Ray, but Label Presses allow you to chase revenue and extreme profit margins. The high GP's for Production Print has already past in most major markets. There's too much competition battling for the slice of the pie with cut sheet opportunities.

Opportunities for GP

If the opportunities to make GP continue to dwindle with MFP's, then how the heck are dealerships going to keep their best sales people. Let's not think about the old dogs like me, but those youngsters that are really good and you can't keep them because another industry offered them better opportunities to make bundles of cash. Do we really want a continuous revolving door with sales people? I don't think so. Wouldn't we want to them to make bundles of cash with us? Sales reps that make bundles of cash is also making piles of profit for the dealer.

Change is Good

There are many discussions in our industry about the need to change, and not be complacent. Yes, you can squeeze more profit from existing MFP accounts, and you can grow your business from acquiring other dealerships. But how long can that business model last with declining pages and everyone stealing each others accounts with net new pricing?

END

Will digital take over Flexo anytime soon? No, I don't thing so. Is there a market for digital ink or laser label presses? Absolutely there is. It's all about becoming a fan of the channel, and doing your homework (just like copiers).

Boy does this bring back memories from my duplicator days!

-=Good Selling=-

Comments (3)